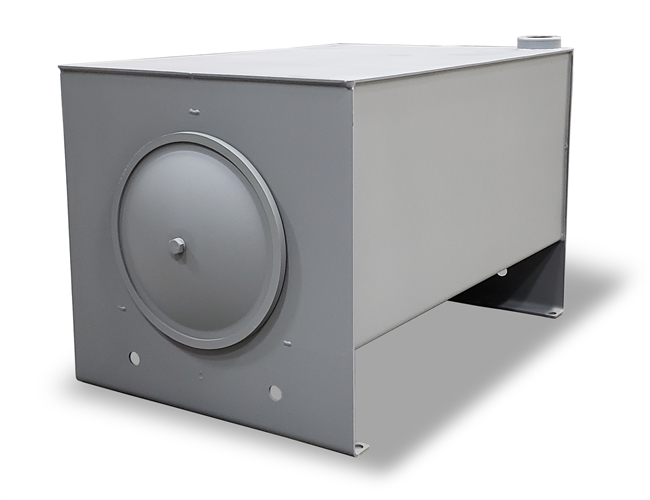

Style A Series Reservoir - JIC Type With Welded Top

View Larger

Additional Product Information

The Style A Series JIC type reservoirs are constructed with a welded top and clean-out access on each end. The reservoir design incorporates a lengthwise baffle positioned between opposing clean-out openings. Each reservoir is supplied with a sight gage, filler breather and access covers.

Standard Features:

- Reservoir capacities ranging from 10 to 700 gallons

- Clean-out access on each end (one access cover has built-in 3/4 inch NPT drain port)

- Reservoir is elevated six inches above mounting surface

- Internal baffle positioned lengthwise between clean-out openings with circulation passages

- Reservoir bottom sloped toward center baffle

- Exterior painted with a LDI gray primer

- Interior coated with rust preventative oil

- 5 inch front mount GT623 Series sight gage (less than 300 gallons)

- 10 inch front mount G1615 Series sight gage (300 gallon and above)

- Card thermometer integral to sight gage, dual scale 0° to 220°F and -20° to 110°C graduations

- 5275 riser for mounting 5201 filler breather

Sight gage and filler breather provided loose with reservoir

Standard Materials:

- Carbon steel reservoir

- Buna N seals

- Sight Gage

- GT623 Series: molded, transparent nylon sight gage with black powder coated steel guard

- G1615 Series: Aluminum construction

- Zinc plated fill cap with nylon strainer basket

Caution:

- Reservoirs are not designed for internal positive or negative pressure applications. For these applications, consult the factory.

Temperature Rating

- Industry accepted design practice for hydraulic systems limits maximum operating temperature to 180° F (82° C), but materials used for fabrication of the reservoirs are capable of operating between -40° and 212° F (-40° and 100° C).

Product Options

Common Modifications Available

- Unpainted (-UP)

- Replace GT623 Series sight gage with an Aluminum sight gage (-AG)

Custom Modifications Available

- EPDM seals

- Suction ports, lines and filters

- Return ports, down pipes and diffusers

- Sight gage locations and features

- Machined mounting plates or blocks

- Mounting studs

- Clean-out geometry and locations

- Modifications to internal baffle

- Heaters and level switches

- Top coat finish

- Component installation and packaging

Minimum quantities may apply.

Related Products

LDI offers other JIC type reservoirs which differ in construction or material.

LDI also offers non JIC type reservoirs to meet a range of applications.

LDI specializes in custom reservoirs with experience designing and fabricating reservoirs of all shapes and sizes to meet our customers' specific needs.

Our capabilities in fabrications go beyond just reservoirs and sheet metal construction. Custom fabrication of brackets, frames and structures is also part of our business supported by our experience in design and manufacture of related products.

CAD Files